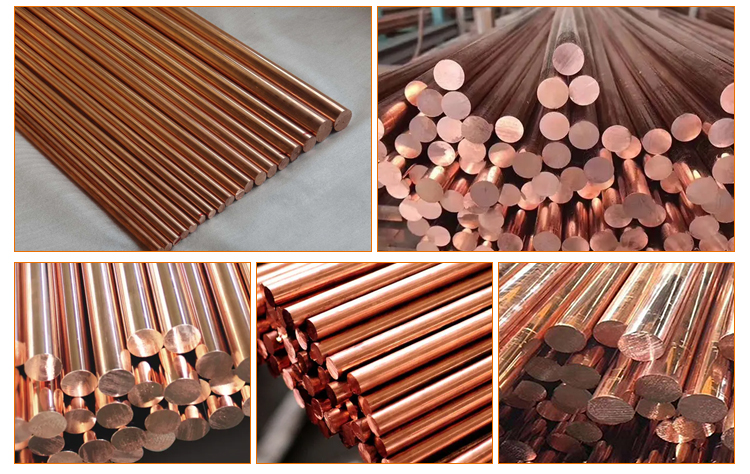

Our Copper Bar is designed to meet all your industrial and commercial needs. Crafted with utmost precision and expertise, this Copper Bar is the epitome of excellence in the metal industry.

Made from premium-grade copper, our Copper Bar boasts exceptional durability and strength, ensuring long-lasting performance and reliability. Its superior conductivity properties make it ideal for various electrical applications, guaranteeing efficient power transmission and minimal energy loss.

With a sleek and polished finish, our Copper Bar not only offers exceptional functionality but also adds a touch of sophistication to any project or application. Its versatile design allows for easy customization and integration into different systems, making it a perfect choice for architects, engineers, and manufacturers.

Whether you require a Copper Bar for electrical wiring, grounding, or even decorative purposes, our product is meticulously engineered to deliver exceptional results. Its corrosion resistance properties ensure longevity, even in harsh environments, making it a reliable choice for both indoor and outdoor applications.

Rest assured, our Copper Bar complies with the highest industry standards, guaranteeing the utmost safety and performance. Each bar undergoes rigorous quality checks and is manufactured with precision, ensuring a consistent and reliable product every time.

Invest in our Copper Bar today and experience the unparalleled quality and performance it offers. Trust in our commitment to delivering excellence, and let our Copper Bar elevate your projects to new heights.

| Product Name | Copper rod |

| Standard | ASTMB152.B187.B133.B301.B196.B441.B465.JISH3250-2006GB/T4423-2007,etc |

Material | C10100,C10200,C10300,C10400,C10500,C10700,C10800,C10910,C10920C10930,C11000,C11300,C11400,C11500,C11600,C12000,C12200,C12300.C12500.C14200.C14420,C14500.C14510C14520.C14530.C17200.C19200C21000.C23000.C26000,C27000,C27400,C28000.C33000,C33200.C37000C44300.C44400.C44500,C60800,C63020,C65500,C68700,C70400,C70620C71000.C71500.C71520,C71640,C72200,etc |

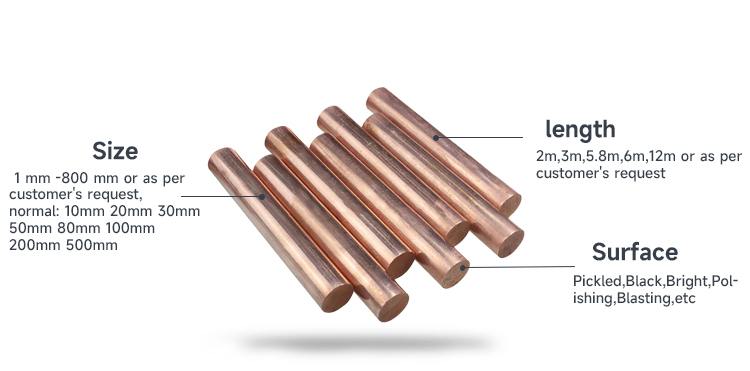

| Diameter | 3mm-800mm |

| Length | 1.0m 5.8m.6m,or as required |

| Container Size | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High)40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High)40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) |

| Price Term | EXW.FOB,CFR,CIF.etc. |

| Application | Copper bar is widely used in boat building.War industry. Car industry and communicationindustry where the components need good wear proof and great corrosion resistance |

Copper bars are widely used in power transmission applications to enhance electrical conductivity. The high electrical conductivity of copper allows for efficient transmission of electricity, reducing power loss and ensuring reliable energy distribution. Copper bars are utilized in power substations, transformer connections, and switchgear systems to facilitate the flow of electricity and maintain optimal performance.

Copper bars play a vital role in electrical grounding systems, which are essential for safety and protection against electrical faults. Copper's excellent conductivity and corrosion resistance make it an ideal material for grounding applications. Copper bars are used in grounding electrodes, grounding grids, and grounding busbars to provide a low-resistance path for electrical current in case of faults, ensuring the safety of personnel and equipment.

Copper bars find extensive use in the manufacturing of various electrical equipment. They are employed in the production of motors, generators, transformers, and other electrical components. Copper's superior electrical conductivity, thermal conductivity, and mechanical properties make it an excellent choice for these applications. Copper bars are utilized for winding coils, forming busbars, and connecting different parts within electrical equipment to ensure efficient operation and longevity.

Copper bars are utilized in heat exchangers and cooling systems due to copper's exceptional thermal conductivity. Heat exchangers transfer heat between two fluids, while cooling systems dissipate heat from equipment or processes. Copper bars are an integral part of these systems, facilitating efficient heat transfer and ensuring optimal performance. They are used as heat exchanger tubes, cooling fins, and heat sink components to maximize heat dissipation and maintain desired operating temperatures.

Copper bars are often utilized for architectural and decorative purposes due to their unique aesthetic appeal and corrosion resistance. In construction, copper bars are employed for roofing, façade cladding, and ornamental elements. Their natural patina over time adds character and visual interest to buildings. Additionally, copper bars are used in interior design, furniture, and artwork, showcasing their versatility and enhancing the overall aesthetic of spaces.

Copper bars find application in various industrial machinery and equipment due to their excellent electrical and thermal conductivity, as well as their durability. They are used in the manufacturing of industrial motors, generators, pumps, and compressors. Copper bars are also employed in welding machines, electrical connectors, and circuit breakers, ensuring reliable electrical connections and efficient operation in demanding industrial environments.

Copper bars are utilized in the automotive and transportation industry for multiple purposes. They are employed in electrical systems, such as wiring harnesses, battery connections, and grounding components, ensuring reliable and efficient electrical performance. Copper bars are also used in heat exchangers for cooling systems in vehicles, contributing to efficient engine operation and preventing overheating.

1、 The conductivity of copper bars is good

Copper is one of the metals with the best conductivity, with a conductivity of up to 56MS/m. Using copper bars as grounding wires can ensure stable and reliable conductivity of the grounding wires, effectively reduce the risk of line faults, and improve the reliability of the power system.

2、 Good corrosion resistance of copper bars

Another advantage of using copper bars as ground wires is their good corrosion resistance. Due to the frequent exposure of power system ground wires to natural factors such as wind, sun, rain, etc., the material of the ground wire must have good corrosion resistance. Copper bars not only resist corrosive media such as water vapor, acid, and alkali, but also withstand high humidity and temperature, making them suitable for long-term use in harsh natural environments.

3、 The contact area between the copper rod and the soil is large

The effective grounding area of the ground wire directly affects the size of the grounding resistance, and the grounding resistance is one of the important indicators to determine the quality of the grounding effect. The copper rod has a large usage area, suitable weight, and a large contact area with the soil, which can effectively improve the grounding effect and ensure the safe operation of the power system.

4、 The diameter of the copper rod has strong adjustability

Another advantage of using copper bars as ground wires is their strong adjustable diameter. The diameter of the ground wire is related to the distribution of current. Compared with steel bars and aluminum bars of the same length, copper bars of the same specification have the best conductivity. For environments with high currents, using thicker copper bars can effectively reduce resistance, provide grounding effect, and avoid bending and fracture problems that may occur during the use of copper bars.

Q1: Do you offer free samples?

A: Sure,we are glad to send you free samples for your evaluation.But currently we need you to kindly pay the delivery charge on your side if you'd like to have our samples.

Q2:How long does your delivery time take?

A:In general, our delivery time is within 7 days, and may be longer if the quantity is extremely large or special circumstances occur.

Q3:Can I go to your factory to visit?

A:Of course, we welcome customers from all over the world to visit our factory.

Q4:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed and customers can appoint third parties to inspect the products before loading too.

Q5:How to pack the products?

A: Standard export sea-worthy packaging, the inner layer has a waterproof paper outer layer with iron packaging and is fixed with a fumigation wooden pallet. It can effectively protect products from corrosion and various climate changes during ocean transportation.

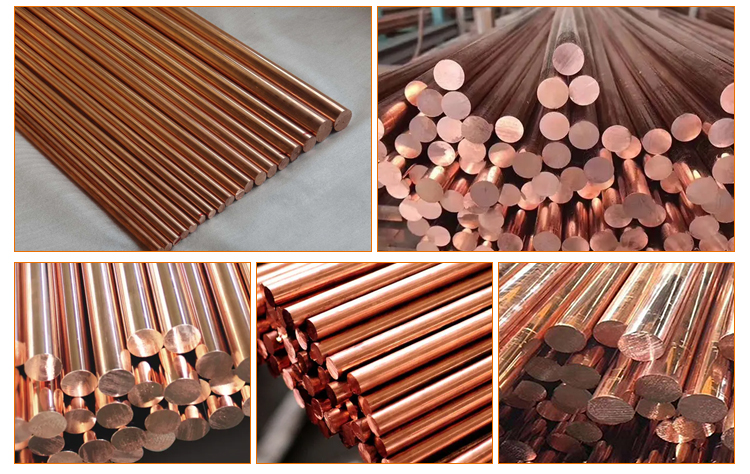

Our Copper Bar is designed to meet all your industrial and commercial needs. Crafted with utmost precision and expertise, this Copper Bar is the epitome of excellence in the metal industry.

Made from premium-grade copper, our Copper Bar boasts exceptional durability and strength, ensuring long-lasting performance and reliability. Its superior conductivity properties make it ideal for various electrical applications, guaranteeing efficient power transmission and minimal energy loss.

With a sleek and polished finish, our Copper Bar not only offers exceptional functionality but also adds a touch of sophistication to any project or application. Its versatile design allows for easy customization and integration into different systems, making it a perfect choice for architects, engineers, and manufacturers.

Whether you require a Copper Bar for electrical wiring, grounding, or even decorative purposes, our product is meticulously engineered to deliver exceptional results. Its corrosion resistance properties ensure longevity, even in harsh environments, making it a reliable choice for both indoor and outdoor applications.

Rest assured, our Copper Bar complies with the highest industry standards, guaranteeing the utmost safety and performance. Each bar undergoes rigorous quality checks and is manufactured with precision, ensuring a consistent and reliable product every time.

Invest in our Copper Bar today and experience the unparalleled quality and performance it offers. Trust in our commitment to delivering excellence, and let our Copper Bar elevate your projects to new heights.

| Product Name | Copper rod |

| Standard | ASTMB152.B187.B133.B301.B196.B441.B465.JISH3250-2006GB/T4423-2007,etc |

Material | C10100,C10200,C10300,C10400,C10500,C10700,C10800,C10910,C10920C10930,C11000,C11300,C11400,C11500,C11600,C12000,C12200,C12300.C12500.C14200.C14420,C14500.C14510C14520.C14530.C17200.C19200C21000.C23000.C26000,C27000,C27400,C28000.C33000,C33200.C37000C44300.C44400.C44500,C60800,C63020,C65500,C68700,C70400,C70620C71000.C71500.C71520,C71640,C72200,etc |

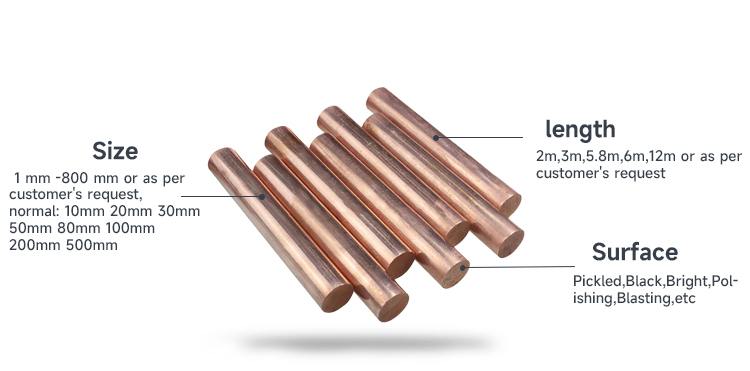

| Diameter | 3mm-800mm |

| Length | 1.0m 5.8m.6m,or as required |

| Container Size | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High)40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High)40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) |

| Price Term | EXW.FOB,CFR,CIF.etc. |

| Application | Copper bar is widely used in boat building.War industry. Car industry and communicationindustry where the components need good wear proof and great corrosion resistance |

Copper bars are widely used in power transmission applications to enhance electrical conductivity. The high electrical conductivity of copper allows for efficient transmission of electricity, reducing power loss and ensuring reliable energy distribution. Copper bars are utilized in power substations, transformer connections, and switchgear systems to facilitate the flow of electricity and maintain optimal performance.

Copper bars play a vital role in electrical grounding systems, which are essential for safety and protection against electrical faults. Copper's excellent conductivity and corrosion resistance make it an ideal material for grounding applications. Copper bars are used in grounding electrodes, grounding grids, and grounding busbars to provide a low-resistance path for electrical current in case of faults, ensuring the safety of personnel and equipment.

Copper bars find extensive use in the manufacturing of various electrical equipment. They are employed in the production of motors, generators, transformers, and other electrical components. Copper's superior electrical conductivity, thermal conductivity, and mechanical properties make it an excellent choice for these applications. Copper bars are utilized for winding coils, forming busbars, and connecting different parts within electrical equipment to ensure efficient operation and longevity.

Copper bars are utilized in heat exchangers and cooling systems due to copper's exceptional thermal conductivity. Heat exchangers transfer heat between two fluids, while cooling systems dissipate heat from equipment or processes. Copper bars are an integral part of these systems, facilitating efficient heat transfer and ensuring optimal performance. They are used as heat exchanger tubes, cooling fins, and heat sink components to maximize heat dissipation and maintain desired operating temperatures.

Copper bars are often utilized for architectural and decorative purposes due to their unique aesthetic appeal and corrosion resistance. In construction, copper bars are employed for roofing, façade cladding, and ornamental elements. Their natural patina over time adds character and visual interest to buildings. Additionally, copper bars are used in interior design, furniture, and artwork, showcasing their versatility and enhancing the overall aesthetic of spaces.

Copper bars find application in various industrial machinery and equipment due to their excellent electrical and thermal conductivity, as well as their durability. They are used in the manufacturing of industrial motors, generators, pumps, and compressors. Copper bars are also employed in welding machines, electrical connectors, and circuit breakers, ensuring reliable electrical connections and efficient operation in demanding industrial environments.

Copper bars are utilized in the automotive and transportation industry for multiple purposes. They are employed in electrical systems, such as wiring harnesses, battery connections, and grounding components, ensuring reliable and efficient electrical performance. Copper bars are also used in heat exchangers for cooling systems in vehicles, contributing to efficient engine operation and preventing overheating.

1、 The conductivity of copper bars is good

Copper is one of the metals with the best conductivity, with a conductivity of up to 56MS/m. Using copper bars as grounding wires can ensure stable and reliable conductivity of the grounding wires, effectively reduce the risk of line faults, and improve the reliability of the power system.

2、 Good corrosion resistance of copper bars

Another advantage of using copper bars as ground wires is their good corrosion resistance. Due to the frequent exposure of power system ground wires to natural factors such as wind, sun, rain, etc., the material of the ground wire must have good corrosion resistance. Copper bars not only resist corrosive media such as water vapor, acid, and alkali, but also withstand high humidity and temperature, making them suitable for long-term use in harsh natural environments.

3、 The contact area between the copper rod and the soil is large

The effective grounding area of the ground wire directly affects the size of the grounding resistance, and the grounding resistance is one of the important indicators to determine the quality of the grounding effect. The copper rod has a large usage area, suitable weight, and a large contact area with the soil, which can effectively improve the grounding effect and ensure the safe operation of the power system.

4、 The diameter of the copper rod has strong adjustability

Another advantage of using copper bars as ground wires is their strong adjustable diameter. The diameter of the ground wire is related to the distribution of current. Compared with steel bars and aluminum bars of the same length, copper bars of the same specification have the best conductivity. For environments with high currents, using thicker copper bars can effectively reduce resistance, provide grounding effect, and avoid bending and fracture problems that may occur during the use of copper bars.

Q1: Do you offer free samples?

A: Sure,we are glad to send you free samples for your evaluation.But currently we need you to kindly pay the delivery charge on your side if you'd like to have our samples.

Q2:How long does your delivery time take?

A:In general, our delivery time is within 7 days, and may be longer if the quantity is extremely large or special circumstances occur.

Q3:Can I go to your factory to visit?

A:Of course, we welcome customers from all over the world to visit our factory.

Q4:Does the product have quality inspection before loading?

A:Of course, all our products are strictly tested for quality before packaging, and unqualified products will be destroyed and customers can appoint third parties to inspect the products before loading too.

Q5:How to pack the products?

A: Standard export sea-worthy packaging, the inner layer has a waterproof paper outer layer with iron packaging and is fixed with a fumigation wooden pallet. It can effectively protect products from corrosion and various climate changes during ocean transportation.

Email:info@hxzhsteel.com

WhatsApp: +86-181 1405 0633

Address: Floor 1, Building 2, No. 1876, Chenqiao Road, Fengxian District, Shanghai, China